Introduction — Enzymes: Nature’s Invisible Powerhouses

Have you ever wondered what makes bread rise, beer ferment, or your body digest food efficiently? The answer lies in a group of extraordinary biological molecules called enzymes. Though invisible to the naked eye, enzymes are the silent workers behind countless natural and industrial processes — from the way our cells generate energy to how industries produce food, beverages, textiles, and more efficiently and sustainably.

Enzymes are biological catalysts, meaning they speed up chemical reactions without being consumed in the process. Without them, life as we know it would move at an impossibly slow pace — food wouldn’t digest, plants wouldn’t grow, and energy production inside cells would stall. Each enzyme is highly specific, designed to carry out one reaction or a family of closely related reactions, making them one of nature’s most efficient tools.

Over the years, scientists and industries have learned to harness the power of enzymes beyond the biological world. Today, enzymes play an essential role in diverse sectors — brewing, baking, dairy processing, animal feed, biofuel production, pharmaceuticals, and even environmental management. They offer eco-friendly alternatives to traditional chemical methods, improving productivity while reducing energy consumption and waste.

At Catalex Bio, we specialize in providing high-quality, application-specific enzyme solutions that help industries unlock greater efficiency, performance, and sustainability. With deep technical expertise and a growing product portfolio, Catalex Bio supports partners across food, beverage, nutraceutical, and biotechnology segments.

This beginner’s guide aims to demystify enzymes — what they are, how they work, why they matter, and how they’re transforming modern industry. Whether you’re a student, professional, or curious reader, this article will help you understand the fascinating world of enzymes and their remarkable impact on our lives.

What Are Enzymes?

Enzymes are remarkable biological molecules that make life possible. In simple terms, an enzyme is a protein (and in some cases RNA) that acts as a biological catalyst, speeding up chemical reactions in living organisms or industrial systems. Every living cell — from bacteria to humans — depends on enzymes for survival. Without them, vital biochemical processes such as digestion, energy production, and DNA replication would proceed far too slowly to sustain life.

At the molecular level, enzymes are composed of long chains of amino acids that fold into intricate three-dimensional structures. This shape is critical because it creates an active site — a specialized region where a specific molecule, known as the substrate, binds. The enzyme then facilitates a reaction that converts the substrate into one or more products. Once the reaction is complete, the enzyme releases the products and is ready to catalyze another reaction, often thousands of times per second.

Enzymes are highly specific — each enzyme typically acts on a single type of substrate or reaction. This specificity arises from the precise fit between the enzyme’s active site and its substrate, often described by the “lock and key” model. In some cases, the enzyme slightly adjusts its shape to fit the substrate better — a concept known as the “induced fit” model.

To make this more relatable:

- The amylase enzyme in your saliva begins breaking down starch from food into sugars even as you chew.

- Proteases in your stomach and intestines cut proteins into amino acids.

- Lipases help digest fats.

These are all examples of enzymes working seamlessly within biological systems. But enzymes are not confined to living organisms — they are now central to many industrial processes because they perform the same efficient catalytic functions outside the body as well.

In essence, enzymes are nature’s nanoscopic machines — perfectly tuned to perform their tasks with unmatched precision and speed. Understanding how they work opens up possibilities across science, health, and industry.

How Do Enzymes Work?

To understand how enzymes function, it’s helpful to think of them as molecular facilitators. Chemical reactions, whether in nature or a laboratory, involve the breaking and forming of chemical bonds. This requires a certain amount of activation energy — the energy barrier that must be overcome for a reaction to proceed.

Enzymes work by lowering this activation energy, making it easier for reactions to occur at normal temperatures and conditions. Here’s a simplified sequence of how an enzyme-catalyzed reaction takes place:

- Substrate Binding:

The enzyme recognizes and binds to its substrate molecule at the active site. This binding is highly specific — much like a key fitting into a particular lock. - Formation of the Enzyme–Substrate Complex:

The enzyme and substrate form a temporary association, stabilizing the transition state — an intermediate form of the reacting molecules. This lowers the energy needed for the reaction to progress. - Catalysis and Product Formation:

The enzyme facilitates the conversion of the substrate into product(s). For instance, in the hydrolysis of starch by amylase, large starch molecules are broken down into smaller sugar molecules. - Product Release:

Once the reaction is complete, the products are released, and the enzyme returns to its original state, ready to repeat the process.

This cyclical action allows enzymes to catalyze thousands of reactions per second with remarkable efficiency and without being consumed in the process.

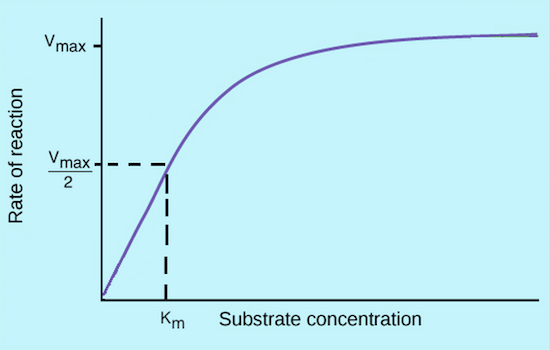

Enzyme Kinetics – Understanding Reaction Rates

The study of enzyme activity and reaction speed is called enzyme kinetics. It provides insights into how efficiently an enzyme converts substrates into products and under what conditions it performs best.

One of the foundational models in enzyme kinetics is the Michaelis–Menten model, which describes the relationship between the reaction rate and substrate concentration. According to this model:

- At low substrate concentrations, the reaction rate increases rapidly as more substrate becomes available.

- As substrate concentration continues to rise, the enzyme’s active sites become fully occupied.

- Beyond a certain point, adding more substrate doesn’t increase the rate — this plateau represents the maximum velocity (Vmax).

- The substrate concentration at which the reaction rate reaches half of Vmax is called the Michaelis constant (Km) — a measure of the enzyme’s affinity for its substrate.

A low Km value indicates high affinity (the enzyme binds strongly to its substrate), while a high Km value suggests lower affinity.

Understanding these parameters helps industries fine-tune enzyme dosages, optimize reaction conditions, and ensure consistent performance in production systems.

Factors Affecting Enzyme Activity

Although enzymes are incredibly efficient, their performance depends on specific environmental and chemical conditions. Variations in temperature, pH, and concentration can greatly influence enzyme behavior. Here are the major factors that affect enzyme activity:

1. Temperature

Enzymes are sensitive to temperature changes. As temperature increases, molecular motion accelerates, leading to a higher rate of enzyme–substrate collisions — and thus faster reactions. However, beyond the optimum temperature, enzymes begin to denature — their structure unfolds, and the active site loses its shape, resulting in a sharp decline in activity.

For most enzymes derived from plants or animals, this optimal temperature lies between 30°C and 45°C, while enzymes from thermophilic microorganisms can function efficiently even at 70°C or higher.

In industrial settings, maintaining the right temperature is crucial — for example, in brewing, mash temperature directly affects the performance of enzymes like α-amylase and protease, influencing the clarity, yield, and flavor of beer.

2. pH

Each enzyme has an optimal pH range where it performs best. Deviation from this range alters the ionization of amino acids in the enzyme’s active site, disturbing substrate binding and reaction efficiency.

For instance, pepsin, an enzyme in the stomach, works optimally in acidic conditions (around pH 2), while amylase in saliva functions best near neutral pH (around 7).

In industrial bioprocesses, the pH must be controlled carefully — even small fluctuations can reduce enzyme efficiency or stability.

3. Substrate Concentration

Increasing substrate concentration generally increases the reaction rate — up to a point. Once all enzyme molecules are occupied (saturated), the rate reaches a maximum (Vmax). Beyond this, adding more substrate has no effect. This principle is crucial when determining enzyme dosage in industrial applications to balance cost and efficiency.

4. Enzyme Concentration

At a constant substrate level, increasing enzyme concentration speeds up the reaction because more active sites become available. However, this is only effective until the substrate becomes the limiting factor. Industrial formulations often optimize both enzyme and substrate concentrations for maximum yield at minimal cost.

5. Inhibitors and Activators

Certain substances can influence enzyme activity:

- Inhibitors slow or stop enzyme activity.

- Competitive inhibitors resemble the substrate and compete for binding at the active site.

- Non-competitive inhibitors bind elsewhere on the enzyme, altering its shape and functionality.

- Activators, on the other hand, enhance enzyme activity by stabilizing the active conformation or assisting in substrate binding.

Industrial enzymes are sometimes engineered for resistance against inhibitors or optimized for stability under challenging process conditions such as high temperature, variable pH, or solvent presence.

6. Cofactors and Coenzymes

Many enzymes require additional molecules known as cofactors (metal ions like Mg²⁺, Zn²⁺, or Fe²⁺) or coenzymes (organic molecules such as vitamins) to function properly. These molecules participate in the reaction or help maintain the enzyme’s structure. Without them, the enzyme may be inactive or unstable.

Practical Relevance in Industry

In industrial biocatalysis, understanding these factors is vital to achieve consistent results. For instance:

- In baking, optimizing temperature and pH ensures stable dough handling and crumb texture.

- In animal feed, enzymes such as phytases must withstand variable digestive conditions.

- In brewing, control of pH and temperature directly impacts clarity, yield, and flavor profile.

Manufacturers like Catalex Bio design and supply enzyme formulations that are optimized for performance under real-world processing conditions. By leveraging insights from enzyme kinetics and stability studies, Catalex Bio helps clients improve efficiency, reduce processing time, and maintain quality consistency across batches.

In short, enzymes operate within a delicate balance of environmental factors and reaction dynamics. Their activity can be finely tuned by adjusting these variables — a principle that forms the basis for both biological regulation in nature and process optimization in modern industry.

Types and Classification of Enzymes

Just as tools in a workshop are designed for specific tasks, enzymes too come in different types — each specialized for a unique reaction. To bring order to this diversity, scientists classify enzymes into six major classes, each performing a distinct type of biochemical transformation. Understanding these classes helps identify how enzymes are applied across industries.

1. Oxidoreductases

These enzymes are involved in oxidation–reduction reactions, where electrons are transferred between molecules. They play a central role in energy metabolism and respiration.

Examples:

- Dehydrogenases and oxidases used in biosensors and diagnostic kits.

- In the food industry, glucose oxidase improves dough stability in baking and enhances the shelf life of products by removing oxygen.

2. Transferases

Transferases transfer functional groups (like methyl, phosphate, or amino groups) from one molecule to another.

Examples:

- Transaminases used in pharmaceutical synthesis for producing amino acid derivatives.

- Kinases, which play a key role in energy metabolism by transferring phosphate groups.

Their precision has made them valuable tools for green chemistry and biomanufacturing.

3. Hydrolases

Perhaps the most widely used class in industry, hydrolases break chemical bonds using water — a process called hydrolysis.

Examples:

- Amylases (break starch into sugars) — vital in brewing, baking, and syrup production.

- Proteases (break proteins into peptides) — used in detergents, leather, and food processing.

- Lipases (break fats into fatty acids and glycerol) — used in dairy, biodiesel, and flavor development.

Hydrolases dominate industrial enzyme markets because they operate efficiently under mild conditions, replacing harsh chemicals in many traditional processes.

4. Lyases

Lyases catalyze the addition or removal of groups from molecules without hydrolysis or oxidation.

Examples:

- Pectin lyase for fruit juice clarification.

- Decarboxylases in fermentation processes that help generate aroma compounds and organic acids.

5. Isomerases

Isomerases rearrange molecules to form isomers — compounds with the same molecular formula but different structures.

Examples:

- Glucose isomerase, used to convert glucose into fructose in high-fructose corn syrup production.

This enzyme has revolutionized the sweetener industry by offering a natural and efficient alternative to chemical catalysis.

6. Ligases (Synthetases)

Ligases catalyze the joining of two molecules using energy derived from ATP.

Examples:

- DNA ligase in biotechnology and molecular biology labs for gene cloning.

- Enzymes used in polymer and peptide synthesis for specialty bioproducts.

In practice, industrial enzyme formulations often combine multiple enzyme types to achieve synergistic effects — for example, a mix of amylase, protease, and glucanase in brewing for optimal starch breakdown and wort filtration.

Understanding these classes allows industries to design more targeted and efficient enzyme-based solutions.

| Enzyme Class | Reaction Type | Example | Industrial Relevance |

|---|---|---|---|

| 1. Oxidoreductases | Catalyze oxidation-reduction (electron transfer) | Glucose oxidase | Food preservation, biosensors |

| 2. Transferases | Transfer functional groups between molecules | Transaminases | Pharmaceutical synthesis |

| 3. Hydrolases | Break bonds using water | Amylase, Protease, Lipase | Detergents, food, leather |

| 4. Lyases | Add or remove groups to form double bonds | Pectin lyase | Fruit juice clarification |

| 5. Isomerases | Rearrange molecular structures | Glucose isomerase | High-fructose corn syrup production |

| 6. Ligases (Synthetases) | Join molecules using ATP | DNA ligase | Molecular biology, biotech R&D |

Among these, hydrolases are the most widely used in industry, accounting for nearly 75% of all commercial enzyme applications.

Enzymes in Everyday Life

Enzymes may sound like specialized scientific tools, but they’re everywhere — quietly improving the quality, efficiency, and sustainability of modern living. From the food we eat to the clothes we wear, and even the fuels that power our vehicles, enzymes play an indispensable role.

1. In Food and Beverages

Food processing is one of the oldest and largest users of enzymes. They help modify taste, texture, appearance, and nutritional value while minimizing the need for chemical additives.

- Baking: Enzymes such as amylase, xylanase, and lipase improve dough handling, loaf volume, and shelf life. Maltogenic amylase, for example, prevents bread staling by modifying starch retrogradation.

- Brewing: Enzymes like α-amylase, β-glucanase, and protease help break down starch, β-glucans, and proteins in malt, improving filtration, flavor, and yield.

- Dairy: Lactase enables the production of lactose-free milk, while lipases contribute to cheese flavor development.

- Juice and Wine: Pectinases and cellulases clarify juices, extract color, and enhance stability.

By replacing chemical additives with natural biocatalysts, enzymes make food production cleaner, safer, and more sustainable.

2. In Healthcare and Diagnostics

Enzymes are vital in medicine and diagnostics. They assist in:

- Digestive enzyme supplements for patients with enzyme deficiencies.

- Diagnostic kits, such as glucose oxidase in blood sugar meters.

- Therapeutic enzymes used to treat specific disorders, such as fibrinolytic enzymes that dissolve blood clots.

Beyond therapy, enzymes are the workhorses of modern biotechnology — powering DNA replication, sequencing, and molecular cloning.

3. In Household Products

In the detergent industry, enzymes such as proteases, lipases, and cellulases are common. They break down protein-based, oily, or starchy stains effectively, even at lower washing temperatures, reducing the need for harsh chemicals and saving energy.

4. In Animal Nutrition

Enzymes in feed formulations help animals better digest plant materials and improve nutrient absorption.

- Phytase releases bound phosphorus from phytate, reducing the need for mineral supplementation and minimizing phosphorus excretion into the environment.

- Xylanase and cellulase improve fiber digestibility in poultry and livestock feed.

By improving feed efficiency, these enzymes contribute to sustainable animal farming.

5. In Environmental Applications

Enzymes play a growing role in bioremediation and waste management, helping degrade pollutants and organic residues. They are also central to the biofuel industry, where cellulases and lipases convert biomass or oils into ethanol and biodiesel. Such processes reduce reliance on fossil fuels and support the transition toward a circular bioeconomy.

Enzymes, though unseen, touch nearly every aspect of our lives. They help industries meet consumer demand for natural, efficient, and eco-friendly products — a vision closely aligned with Catalex Bio’s mission of enabling biological solutions for modern challenges.

Industrial Use of Enzymes

While nature uses enzymes to sustain life, industries use them to drive efficiency, innovation, and sustainability. The industrial enzyme market continues to expand, powered by biotechnology advances and growing demand for greener alternatives to chemicals.

Let’s look at how enzymes are transforming major sectors — and how Catalex Bio supports these applications.

1. Food and Beverage Processing

Enzymes have become indispensable in improving product quality and production efficiency.

- Baking enzymes such as amylase, xylanase, and maltogenic amylase optimize dough stability and freshness.

- Brewery enzymes like α-amylase, β-glucanase, and protease enhance extract yield, reduce viscosity, and improve filterability and flavor.

- Juice and wine enzymes such as pectinase and cellulase increase clarity and color extraction.

Catalex Bio offers tailored enzyme solutions to address these applications. For more on brewing-specific formulations, explore our Brewery Enzyme Solutions.

2. Animal Feed and Nutrition

Animal feed enzymes help maximize nutrient utilization and reduce waste.

- Phytases release bound phosphorus, improving feed conversion efficiency.

- Xylanases and cellulases help break down plant fibers for better digestibility.

- Proteases enhance amino acid availability, supporting animal growth and health.

Catalex Bio’s enzyme products are developed to ensure high stability under pelleting and gastrointestinal conditions, delivering consistent results in poultry, aquaculture, and livestock nutrition.

3. Biofuel and Biochemical Production

As industries shift toward sustainable energy, enzymes play a key role in biofuel production.

- Cellulases and hemicellulases break down plant biomass into fermentable sugars for bioethanol.

- Lipases catalyze the transesterification of oils into biodiesel.

These processes operate under mild, eco-friendly conditions, avoiding toxic catalysts and reducing energy consumption.

4. Textiles, Paper, and Leather

- In the textile industry, enzymes such as cellulase are used for fabric biopolishing, giving smoother texture and brighter colors.

- In paper and pulp, xylanases help bleach pulp using fewer chemicals, reducing chlorine use and effluent load.

- In leather processing, proteases and lipases replace harsh dehairing and degreasing chemicals, resulting in safer and cleaner operations.

5. Biotechnology and Specialty Applications

Enzymes are also central to high-value biotechnological processes, such as producing pharmaceuticals, nutraceuticals, and cosmetic ingredients. Catalex Bio supports clients in these specialized sectors by supplying enzymes optimized for purity, performance, and regulatory compliance.

Why Industries Prefer Enzymes

Compared to conventional chemical catalysts, enzymes offer several advantages:

- Specificity: They act only on desired substrates, reducing side reactions.

- Mild operating conditions: They function effectively at moderate temperatures and neutral pH.

- Biodegradability: Enzymes are environmentally safe and leave no toxic residues.

- Energy and cost efficiency: Faster reactions mean lower energy use and shorter processing time.

These benefits translate into more sustainable, cost-effective, and cleaner industrial operations — aligning perfectly with global trends toward green manufacturing.

Catalex Bio’s Role

At Catalex Bio, we combine technical expertise with strong supplier partnerships to deliver reliable enzyme solutions tailored to each industry’s process conditions. Whether optimizing mash filtration in brewing, enhancing dough performance in baking, or improving feed efficiency in animal nutrition, our enzyme formulations are designed for consistency, efficacy, and sustainability.

Through continuous innovation and collaboration, Catalex Bio aims to make enzyme technology more accessible to industries seeking high-performance biological solutions that also reduce their environmental footprint.

Enzymes and Sustainability

In recent years, sustainability has become more than a buzzword — it’s now a global priority. As industries face increasing pressure to reduce emissions, minimize waste, and conserve resources, enzymes have emerged as a cornerstone of green innovation.

Enzymes are inherently sustainable because they are biodegradable, operate under mild conditions, and replace harsh chemical catalysts that often produce toxic by-products. By enabling reactions to occur at lower temperatures and neutral pH levels, enzymes significantly reduce energy consumption and water usage — two major sustainability metrics across manufacturing sectors.

1. Reducing Environmental Impact

Traditional industrial processes often depend on strong acids, alkalis, or solvents. These can be energy-intensive and generate harmful waste streams. Enzymatic processes, by contrast, are more selective and cleaner.

For example:

- In textile processing, cellulases and amylases replace aggressive chemicals in fabric finishing.

- In paper and pulp, xylanases help bleach pulp with less chlorine, reducing chemical oxygen demand (COD) in effluent.

- In detergents, enzymes allow effective cleaning at lower temperatures, saving electricity and water.

Such applications demonstrate how enzymes help industries meet environmental regulations while improving efficiency.

2. Enhancing Resource Efficiency

By improving yield and conversion rates, enzymes help industries extract more value from the same raw material.

- In brewing, enzymes increase extract recovery from grains.

- In feed, they unlock nutrients that would otherwise remain inaccessible.

- In biofuels, they enable higher ethanol yields from renewable biomass sources.

This efficient use of resources contributes directly to circular economy principles — maximizing productivity while minimizing waste.

3. Supporting Renewable and Bio-Based Production

Enzymes are at the heart of the bioeconomy — an emerging framework where renewable biological resources are used to produce food, materials, and energy. Biocatalysis (enzyme-driven catalysis) is already replacing petroleum-based chemical synthesis in producing flavors, fragrances, pharmaceuticals, and specialty chemicals.

Catalex Bio actively promotes enzyme-based technologies as sustainable alternatives to traditional processing. By supplying optimized, high-performance enzyme formulations, we help clients reduce energy consumption, lower chemical inputs, and improve product quality — all while aligning with their environmental goals.

In short, enzymes are not just tools for efficiency — they are agents of sustainable transformation, shaping the way industries think about production and the planet.

The Future of Enzyme Technology

The story of enzyme technology is still being written — and the next chapters promise even greater innovation. With rapid advances in biotechnology, genomics, and computational design, scientists are now engineering enzymes with improved properties, opening doors to new applications once thought impossible.

1. Enzyme Engineering and Directed Evolution

Modern enzyme development increasingly relies on protein engineering — modifying an enzyme’s structure to enhance performance, stability, or specificity. Through techniques like directed evolution, researchers mimic natural selection in the laboratory, generating enzyme variants with desired traits such as higher thermal stability or tolerance to extreme pH.

These engineered enzymes are already revolutionizing industries — from biofuels and pharmaceuticals to specialty chemicals — by making previously inefficient processes commercially viable.

2. Immobilized and Reusable Enzymes

Traditional enzymes are soluble and used once per batch. However, immobilized enzymes — bound to solid supports — offer reusability and easier separation from products. This technology is widely adopted in continuous bioprocesses like high-fructose syrup production (using immobilized glucose isomerase).

Immobilization improves enzyme stability, reduces waste, and enhances process economics — making it a promising area for sustainable manufacturing.

3. Computational Design and Artificial Intelligence

Advances in AI-driven modeling and machine learning now allow researchers to predict enzyme structures and design them virtually before laboratory testing. AI tools can simulate how enzymes interact with substrates, helping identify better candidates in less time and at lower cost.

This fusion of biology and computation is accelerating enzyme discovery — leading to tailor-made biocatalysts for specific industrial needs.

4. Expanding Applications in Emerging Fields

As new sectors embrace biotechnology, enzyme applications continue to expand:

- Bioplastics: Enzymes assist in the synthesis and degradation of biodegradable polymers.

- Nutraceuticals: Enzymes help extract active compounds and improve bioavailability.

- Cosmetics: Lipases and proteases are used in natural formulations for skincare and exfoliation.

- Waste Valorization: Enzymes convert organic waste into valuable products such as biofertilizers or biogas.

Catalex Bio stays closely aligned with these innovations, collaborating with research partners and clients to explore emerging enzyme applications that drive both performance and sustainability.

5. Democratizing Enzyme Access

Another important trend is making enzyme technology more accessible to smaller manufacturers and developing markets. Historically, enzyme use was limited to large corporations due to cost and technical know-how.

Today, with improved production efficiency, global supply networks, and technical support from companies like Catalex Bio, more businesses — from regional breweries to small-scale feed mills — can benefit from the power of enzymes.

The future of enzyme technology lies in this democratization — where every industry, regardless of scale, can integrate enzymes for better productivity and a lighter environmental footprint.

Conclusion

From the moment you wake up — brushing your teeth (thanks to enzymes in toothpaste) — to your meals, clothes, and even the fuel that powers your commute, enzymes are everywhere. They are nature’s catalysts, working silently to make life and industry more efficient, cleaner, and sustainable.

Understanding enzymes is the first step toward appreciating their impact. They bridge biology and technology, providing a model for innovation that is both scientifically elegant and environmentally responsible. As industries move toward greener solutions, enzyme-based processes will continue to play a defining role in shaping a sustainable future.

At Catalex Bio, we are proud to be part of this transformation. Our focus is on helping industries harness the potential of enzymes — whether to improve food quality, enhance fermentation efficiency, boost feed performance, or support next-generation bioprocessing. With a strong portfolio of enzyme solutions and technical expertise, we provide partners with reliable, high-performance biocatalysts tailored to their needs.

Your Next Step

If you’re exploring ways to integrate enzymes into your process — be it in food, feed, beverage, or specialty applications — our team can help.

👉 Reach out to Catalex Bio to discover how our enzyme solutions can enhance your efficiency, sustainability, and product performance.

Visit www.catalexbio.com to learn more, or connect with us for customized recommendations that fit your unique process requirements.

Enzymes are the future of sustainable industry — and at Catalex Bio, we’re helping build that future, one catalytic reaction at a time.

Pingback: Enzyme Buyer’s Glossary by Catalex Bio | Key Terms & Definitions

Pingback: Cellulase Enzyme Uses & Benefits | Catalex Bio

Pingback: Global Enzyme Market 2025 Insights | Leading Enzyme Manufacturer & Supplier Catalex Bio

Pingback: Maltogenic Amylase Manufacturer & Supplier | Baking Applications & Anti-Staling Enzyme

Pingback: Juice Processing Enzymes by Catalex Bio: Boost Yield & Clarity

Pingback: Why Higher Enzyme Dosage Doesn’t Always Improve Performance in Industrial Processes - CATALEX BIO